There was change in process since the measurement began. I was going to measure most, if not all, of the parts before beginning CAD modeling but it didn't workout as I thought. I had to measure as I model each parts. Modeling required far more improvisation than expected.

So the initial modeling took longer, but it was somewhat expected. Always expect plan change, looks like.

Anyway, modeling began with the main body of the watch and all the parts were built around it.

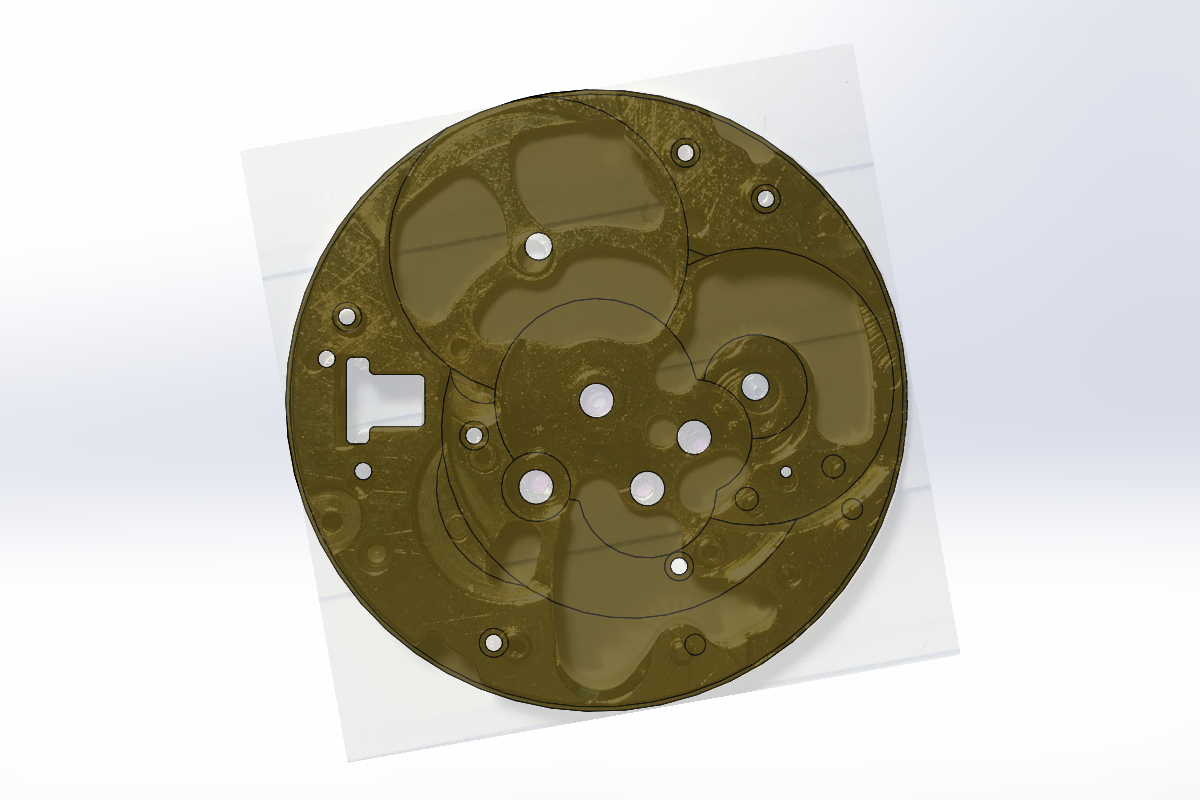

Front of the main body. A picture is better than dozens of numbers.

Overlaying picture helps a lot in improvising work.

Back of the main body in work. Works the same way as the front.

A lot of mid-steps are not shown but result was reasonable. It's not perfectly like the original but it's fine at the moment I guess.

Exploded view with a bit of self satisfacton of work done.

There was other difficulty in modeling parts. All the disassembling process was video recorded so that in the future I will be able to associate which part does what and located where, but the footage got lost... Manually figuring out the lost information... were not easy.

The next step will be to make numbers reasonable, especially the gears. This will change things a bit, location wise and what not.